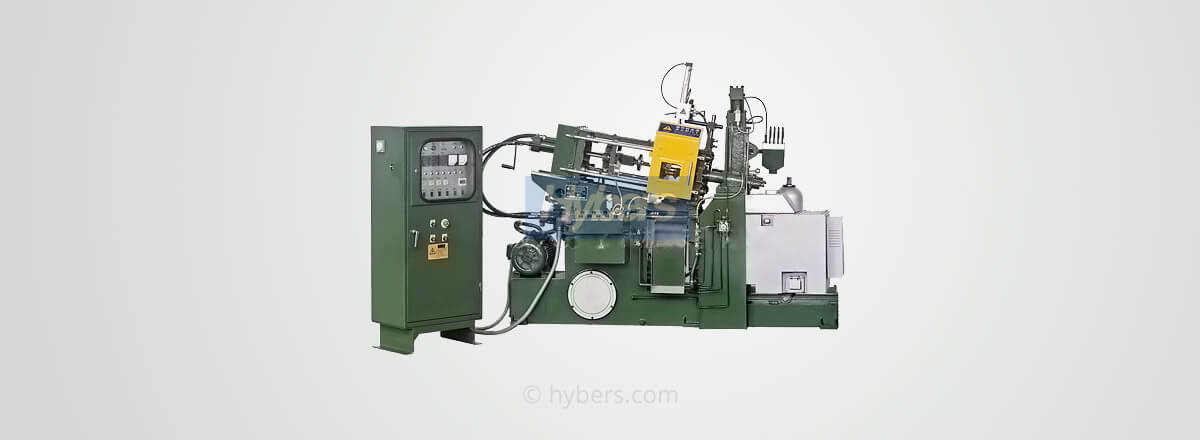

The machine is applicable to die casting of non-ferrous metals with low melting point such as Zn(Zinc) and Pb(Plumbum). It is widely used in various industries including automobile and motorcycle parts, meters and instruments, daily-use hardware, and household appliance etc.

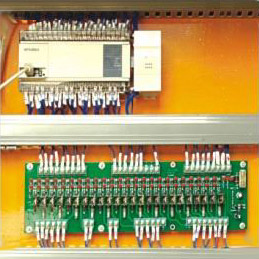

The machine is controlled by industrial level microcomputer. The die casting process parameters can be set up through the HMI, which is convenient and time-saving and effortless in operation and maintenance.

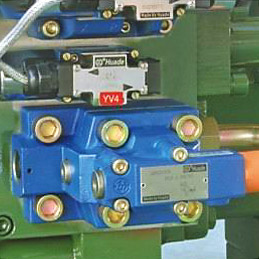

The hydraulic system of the machine adopts the flow and pressure double-scale system so that flow and pressure can be adjusted at discretion. The ejection system uses large-caliber logic and cantilever bean-type oil way, which ensures high ejecting speed.

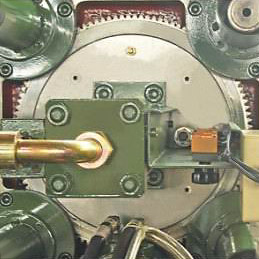

The machine is equipped with imported electronic and hydraulic parts, ensuring a reliable and safe whole-machine performance.

The machine is controlled by industrial level microcomputer. The die casting process parameters can be set up through the HMI, which is convenient and time-saving and effortless in operation and maintenance.

The hydraulic system of the machine adopts the flow and pressure double-scale system so that flow and pressure can be adjusted at discretion. The ejection system uses large-caliber logic and cantilever bean-type oil way, which ensures high ejecting speed.

The machine is equipped with imported electronic and hydraulic parts, ensuring a reliable and safe whole-machine performance.

specification

parameters

features

Adopting computers and contactors of world famous brand.

Imported touchscreen for die casting machine.

Central electric lubrication system.

Low pressure mould protecting system.

Hydraulic drive planetary gear mold adjust device.

Solid mold frame system.

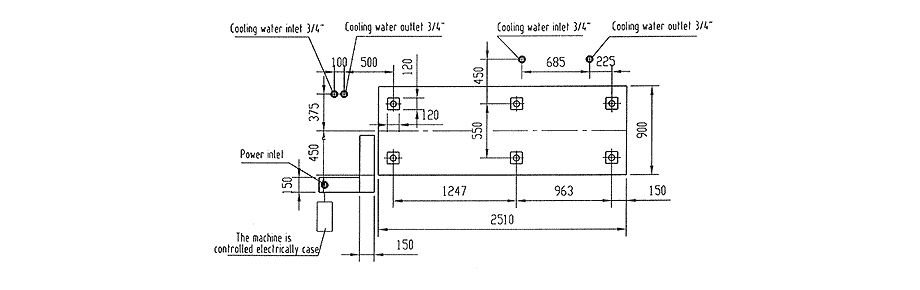

installation

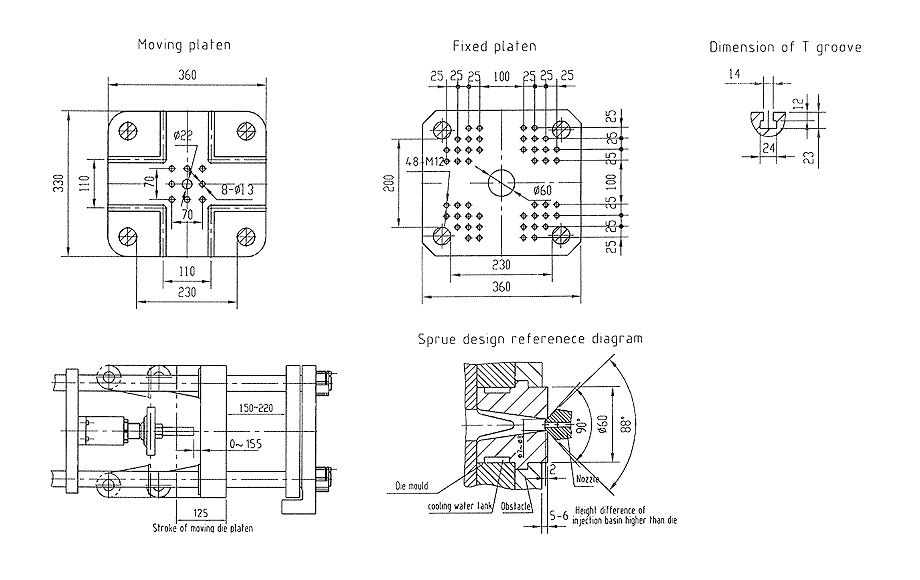

mold plate size